Revolutionary Black CubeSat Solar Cell Technology

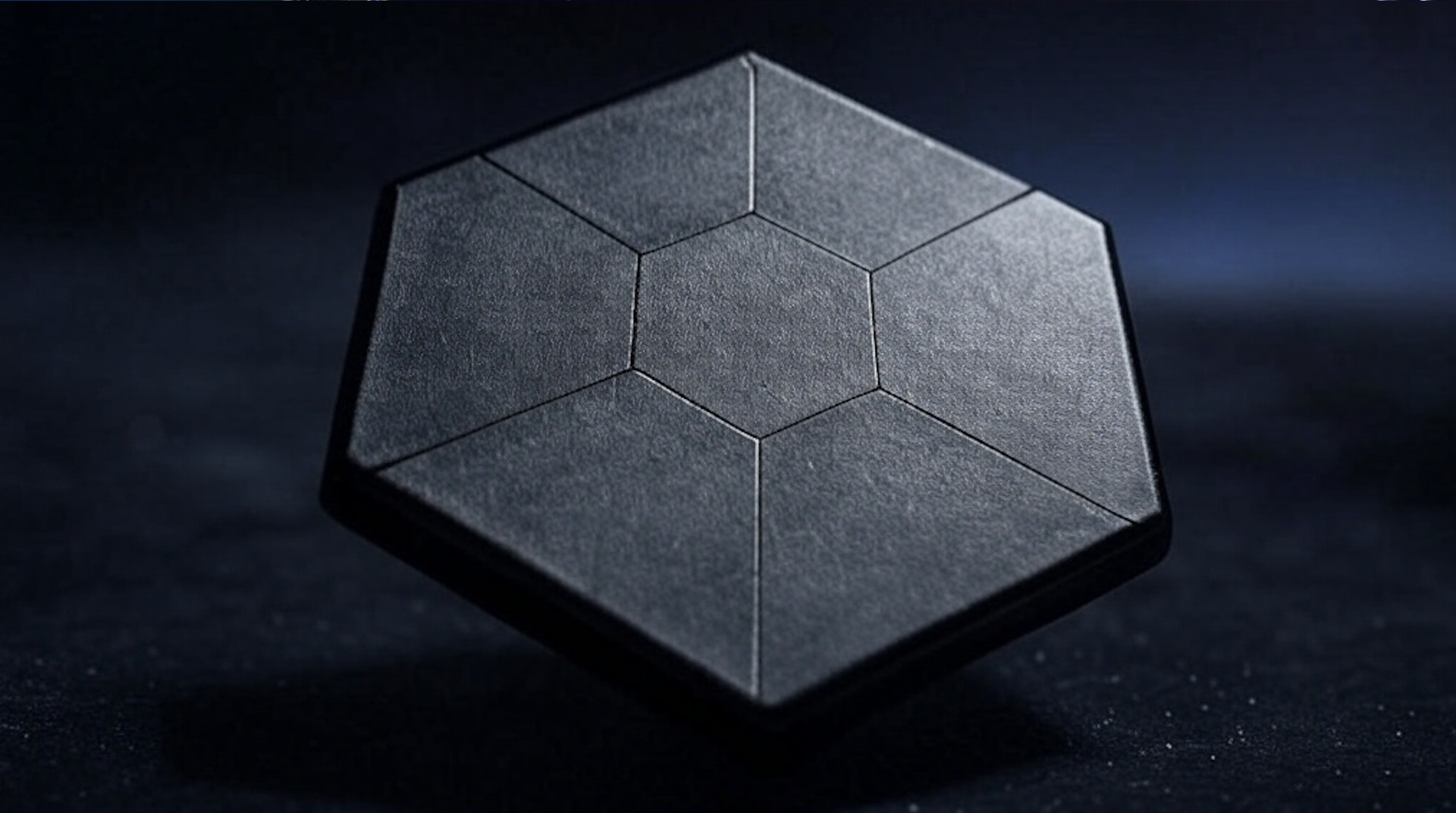

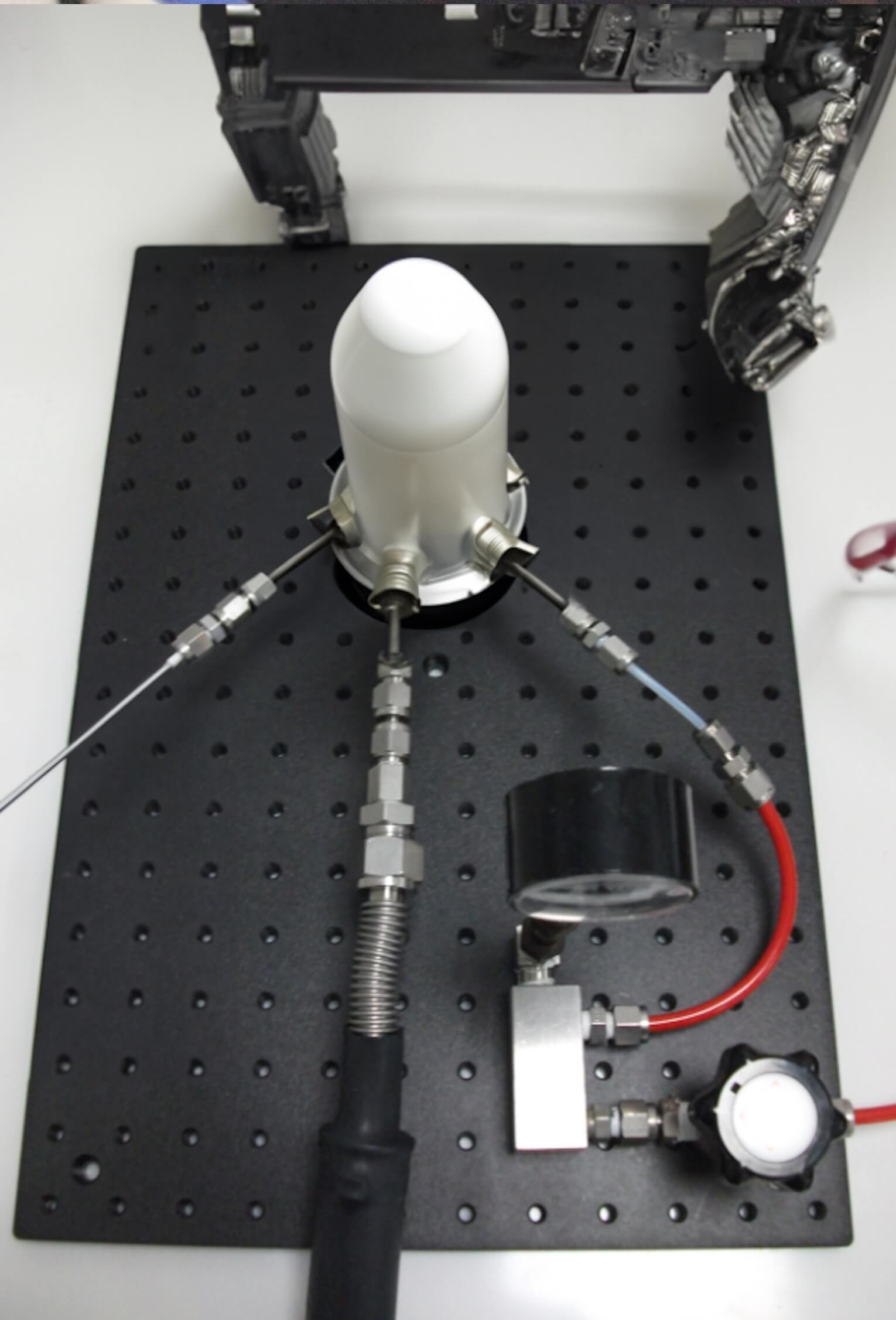

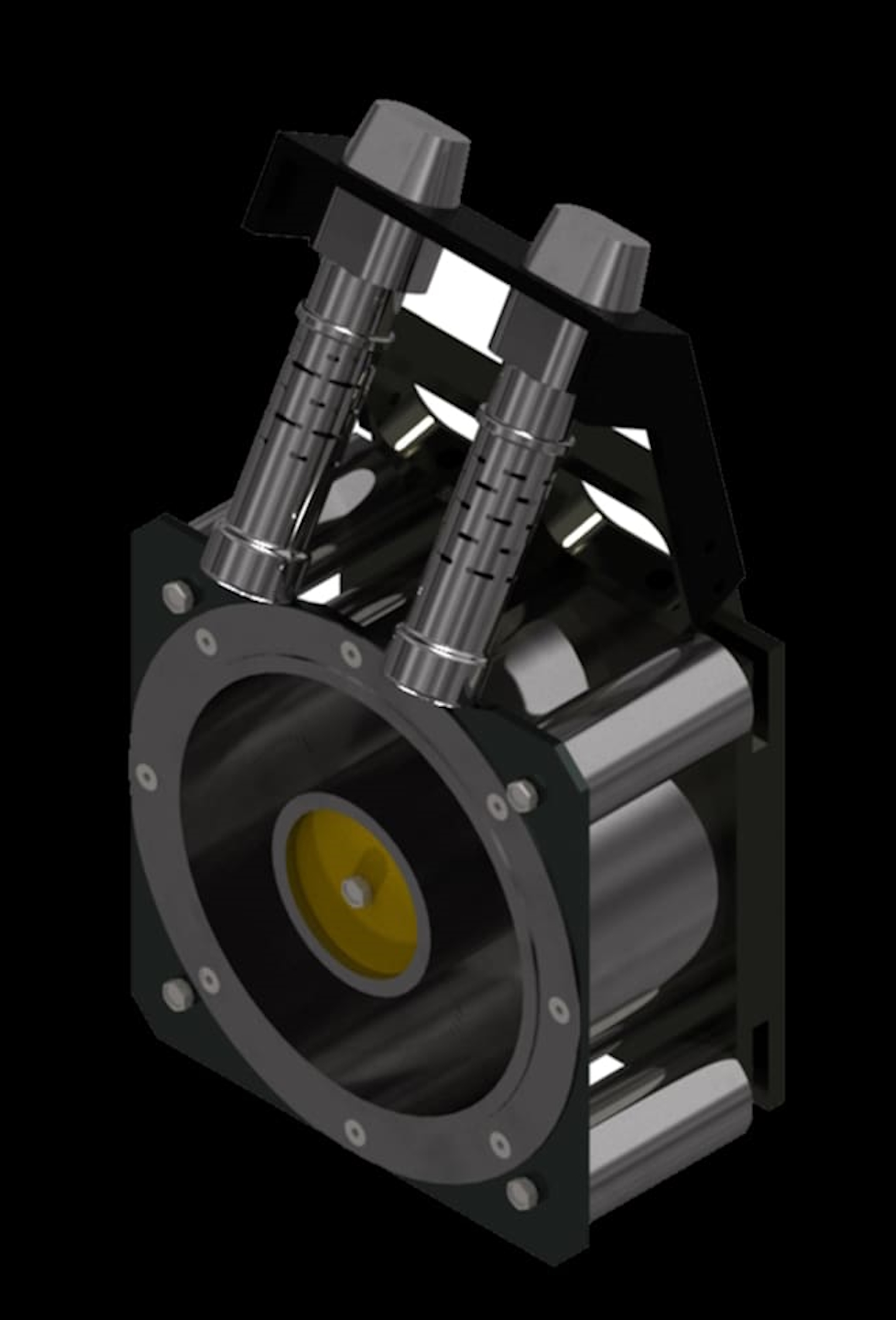

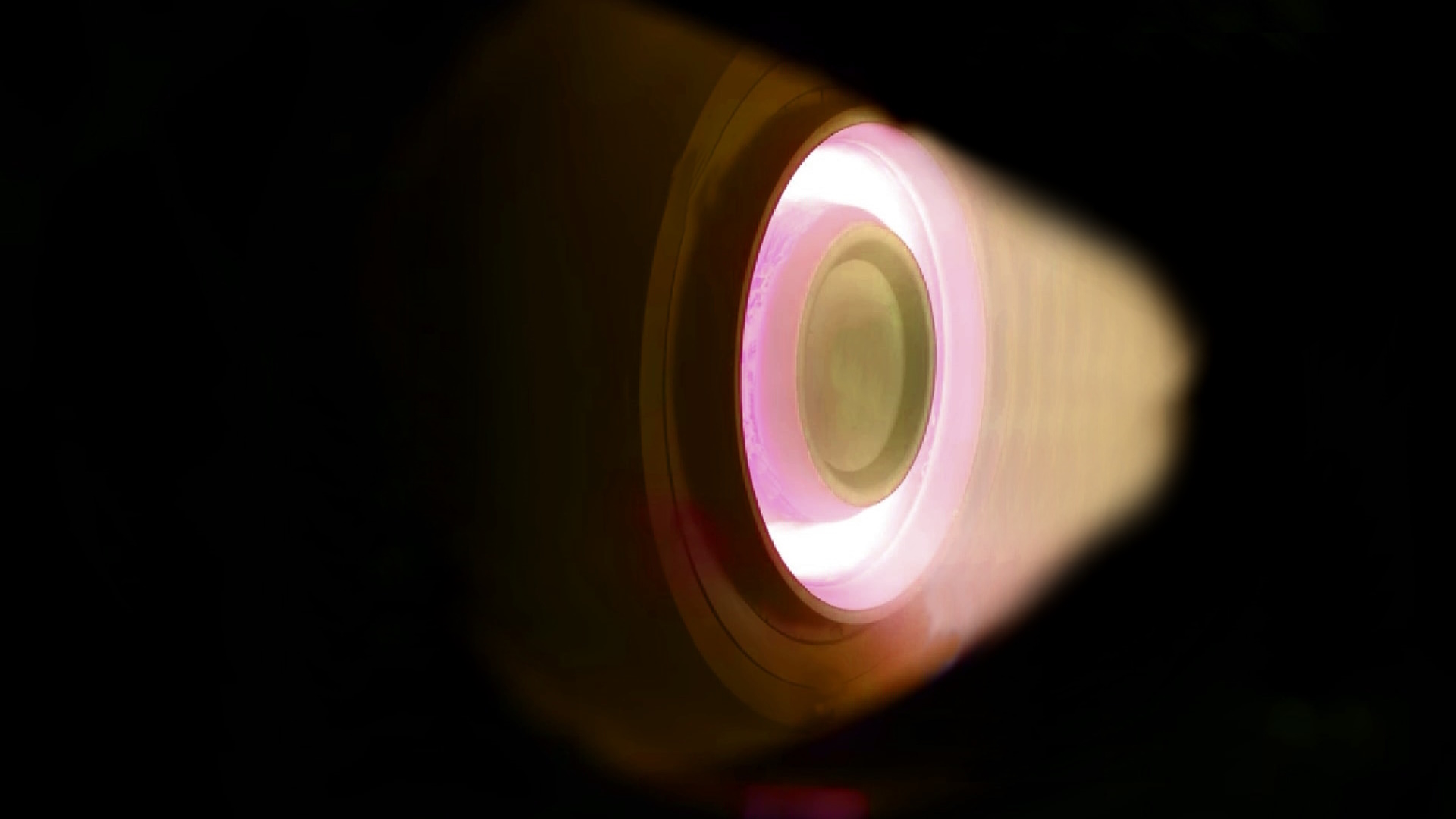

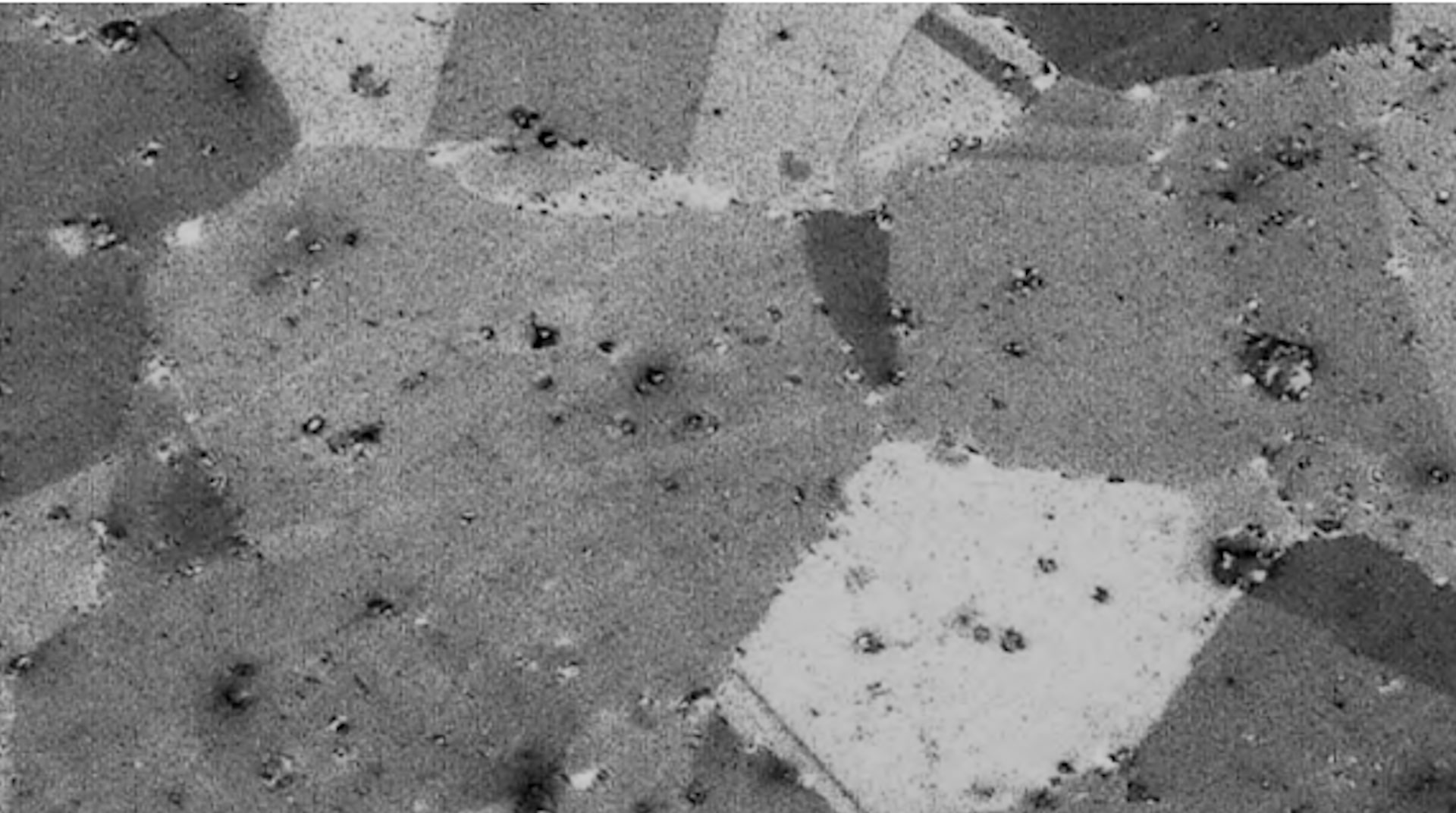

Infinity Space is at the forefront of CubeSat energy solutions with the development of our innovative Black CubeSat Solar Cell, designed to meet the unique challenges of space-based applications. Utilising high-purity III-V semiconductor materials, our solar cells are optimised for superior performance in the extreme conditions of outer space.

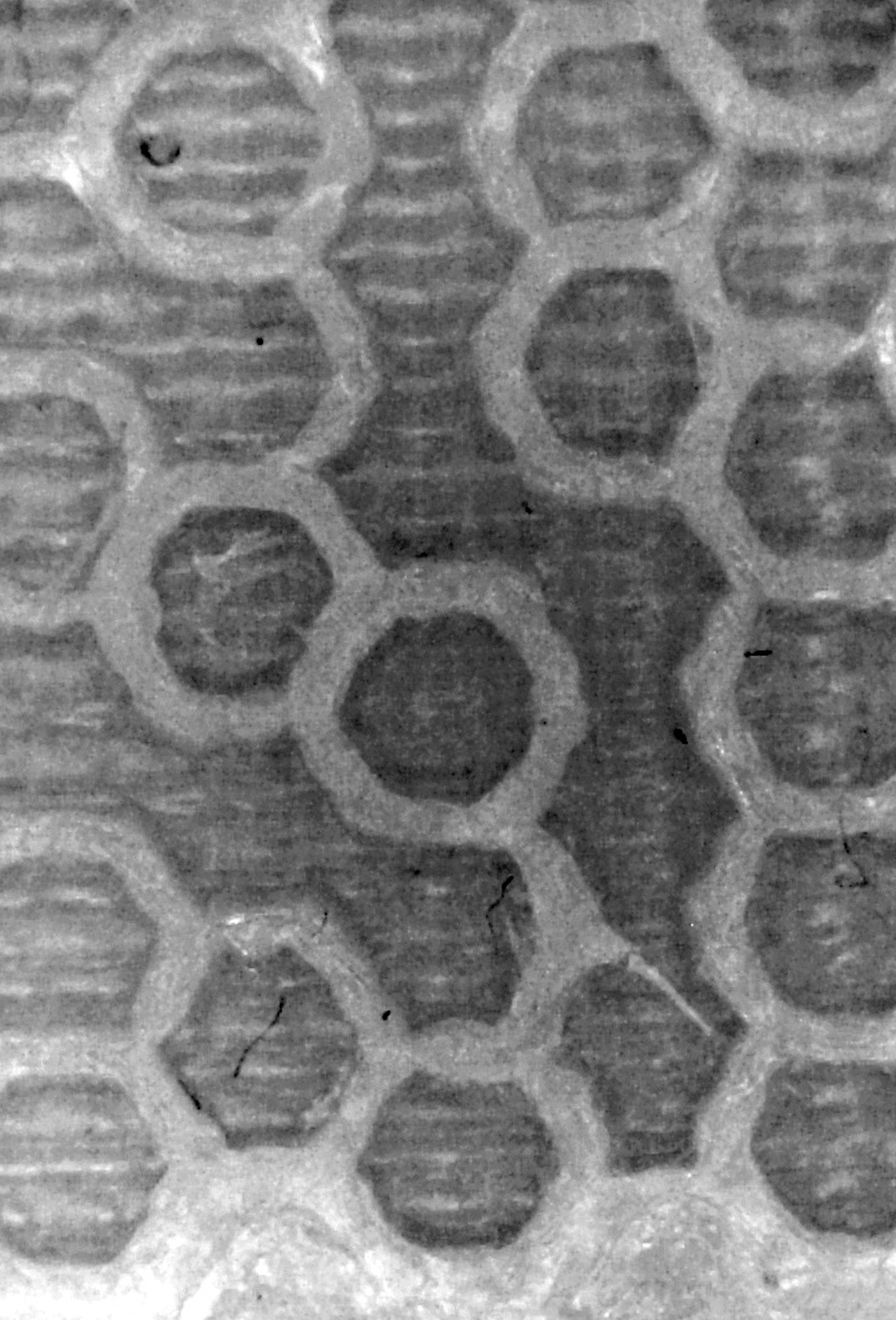

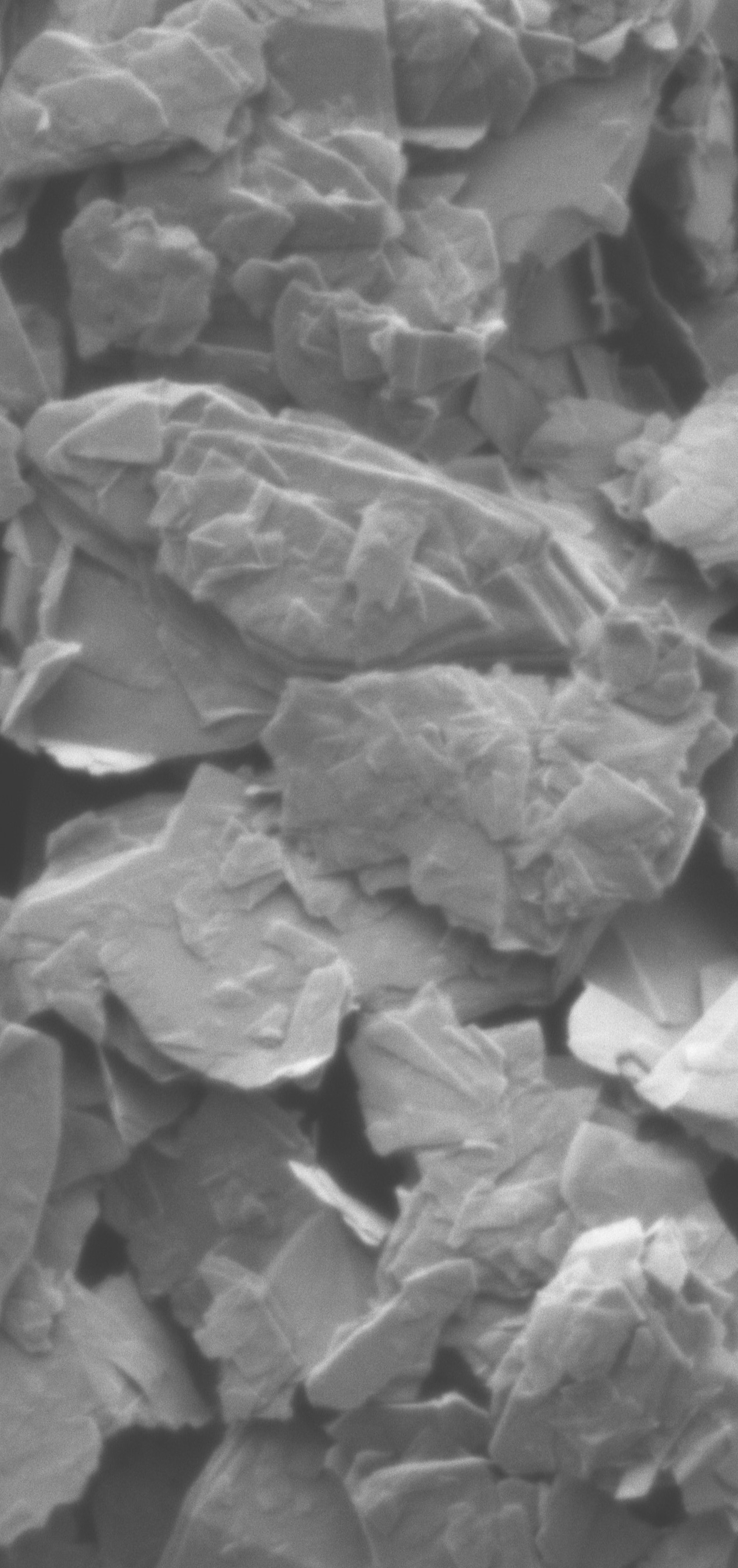

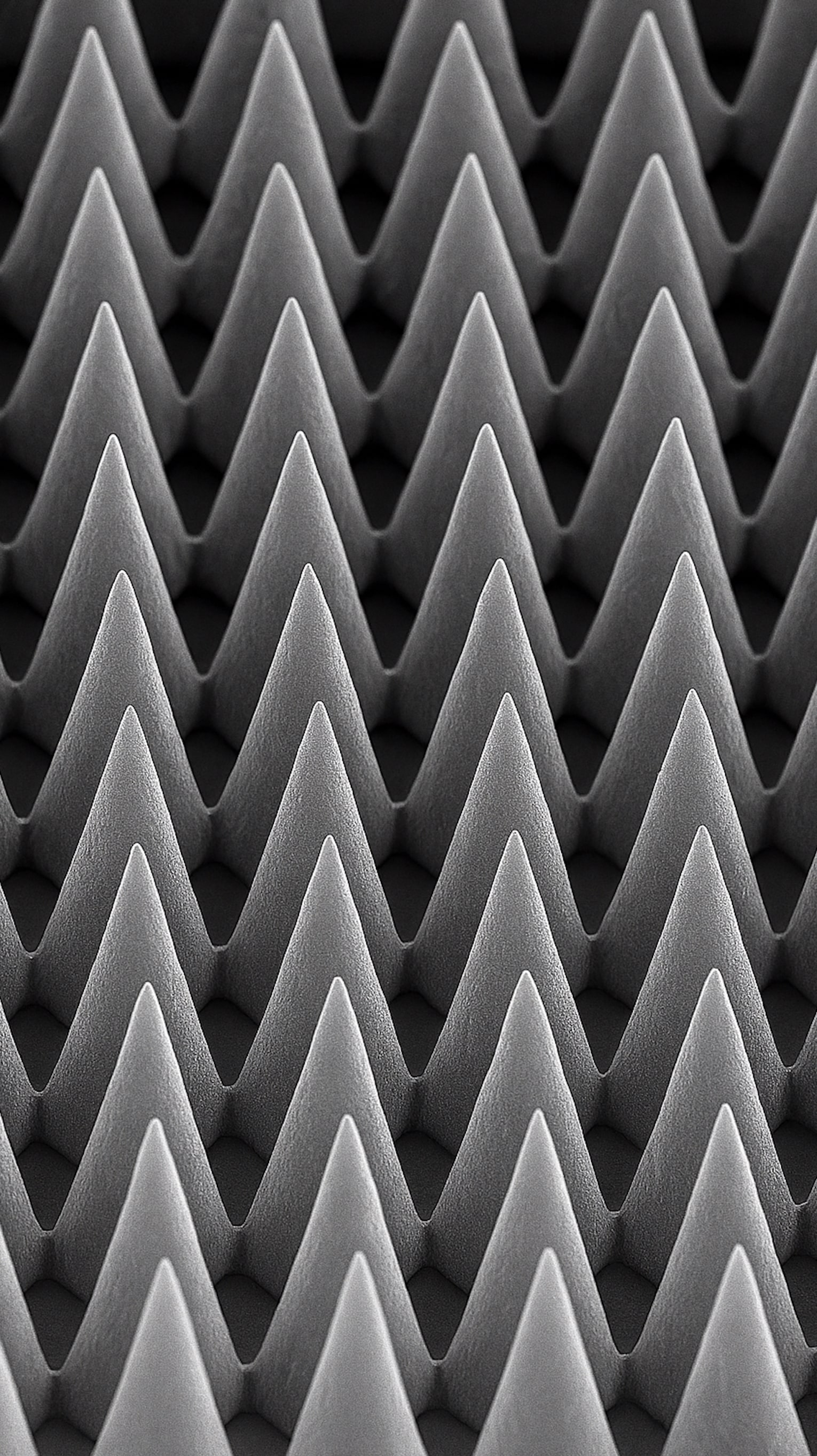

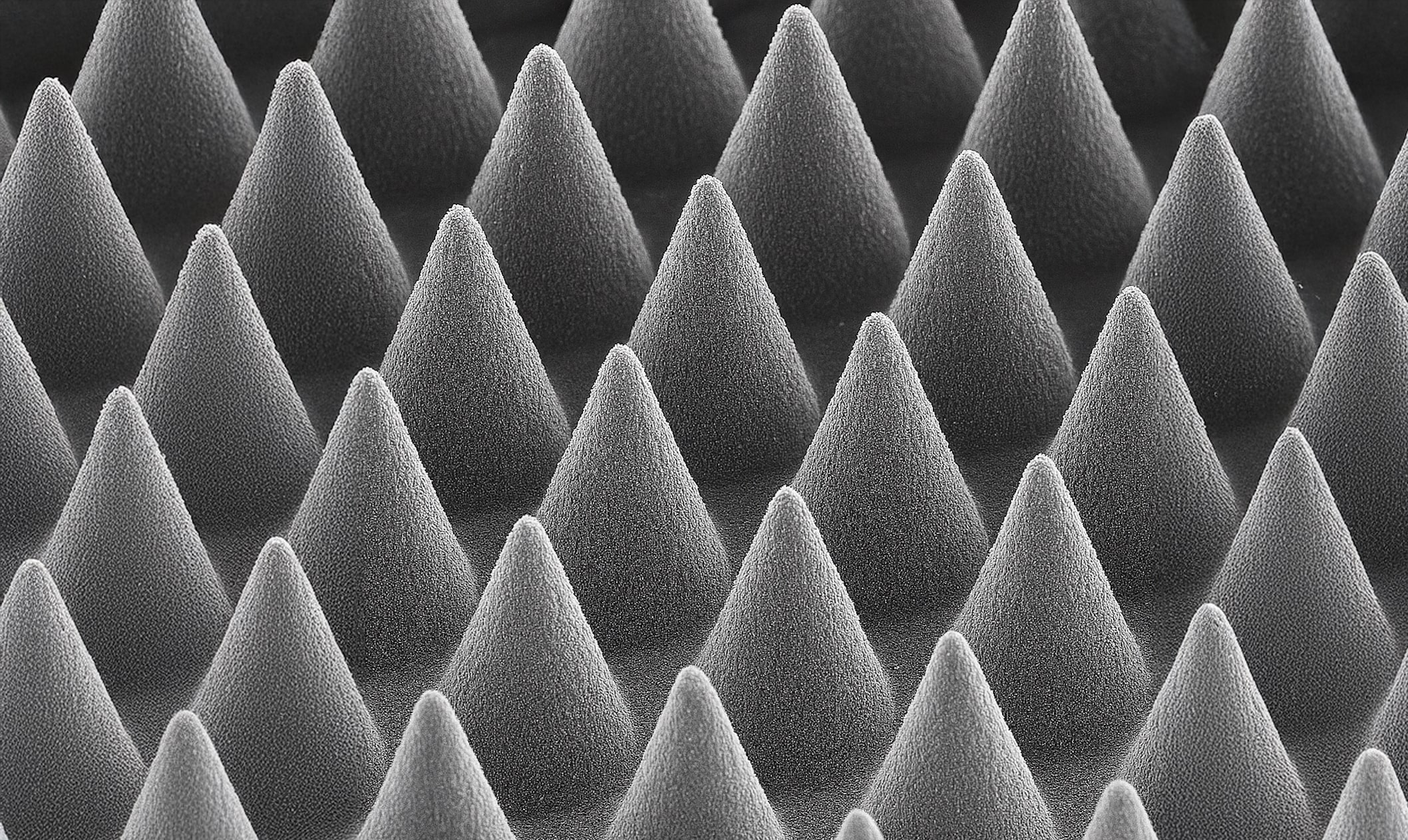

A key technological advancement in our solar cell design is the integration of advanced backside texturing. This process enhances the cell’s light absorption capabilities by increasing the effective surface area, allowing for improved photon capture and conversion. The optimised surface structure significantly reduces reflectance and maximises the amount of incident light that is absorbed, leading to superior energy generation efficiency under space conditions.

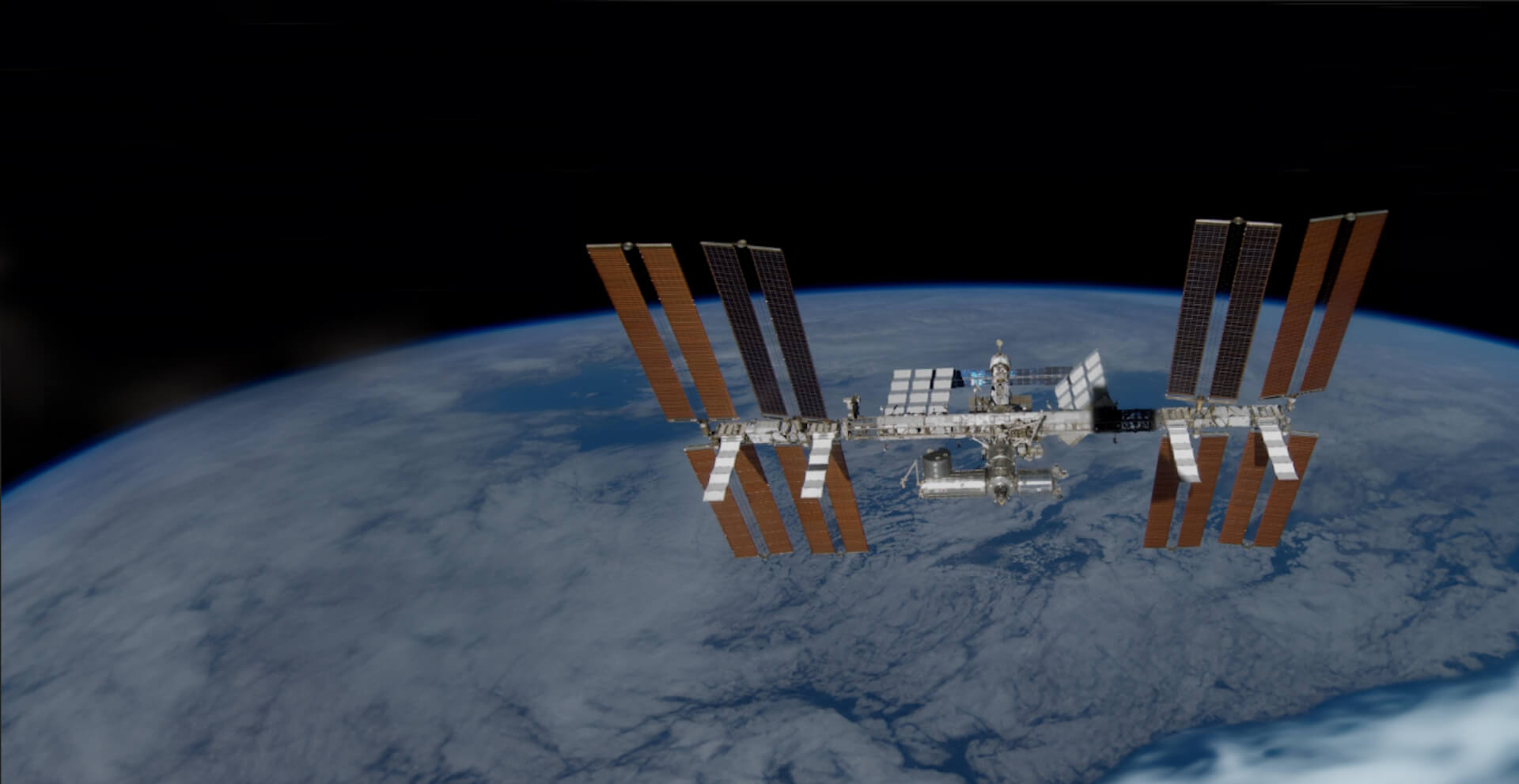

The Black CubeSat Solar Cell demonstrates a remarkable >30% efficiency under AM0 (Air Mass Zero) conditions, which represents the solar flux outside Earth’s atmosphere. This efficiency is achieved through the combination of high-performance III-V materials and precise structural engineering, ensuring that the cell can capture and convert the maximum possible amount of solar radiation for CubeSat operations in low-Earth orbit (LEO) or beyond.